One-stop PCB Manufacturing & PCBA Service

Get The Best Solution for Your Project

We Respect Your TIME In PCB Manufacturing Process

We understand how important for your to select reliable manufacturer and inspect the quality of the PCB Prototype for your own applications. We respect your time and our own time as well. Before we provide the quotation, our engineering team will provide free DFM evaluation for your Gerber or BOM file. Therefore we can offer our suggestion to your PCB design and provide solutions from manufacturing process. Blow are some brief numbers of our factory.

We Have The Confidence to Become Your Specific Solution Provider and Manufacturer for Printed Circuit Boards!

Since 2004, QCX ELECTRONIC CO., LIMITED is aiming to become the leading manufacturer in the field of printed circuit boards. To achieve our goals, we make every effort to improve our quality standards and our services. Through the years, we’ve got certifications like ISO:9001, ISO:14001, IATF16949, UL for USA, UL for Canada, CE and RoHS, etc. We’re dedicated to making high-end quality printed circuit boards, including rigid PCB, flex PCB, rigid-flex PCB, metal core PCB. In each type of PCBs, we are capable of making multi-layer PCB, high-frequency PCB, Hi-Tg heavy copper PCB, mixed dielectric base PCB, HDI PCB, and many other customized PCB with special requirements and performance according to your specific needs.

Professional Advices

Our engineer will provide suggestions on customer's designs and help to improve Gerber's design from the manufacturing process perspective.

Diversified Raw Material

We can supply a wide variety of raw materials, such as Fr-4(TG130~TG170)/IT180A/CME1/CEM3/Rogers/ISOLA/PI materials/Metal material etc.

Quality Control Process

In the whole production, we will perform 3 times quality testing: materials testing, semi-finish testing, finished-item testing.

24/7 After-Sale Services

We take responsibility for every item we provided to our customers. We guarantee that we take care of every issue from our client.

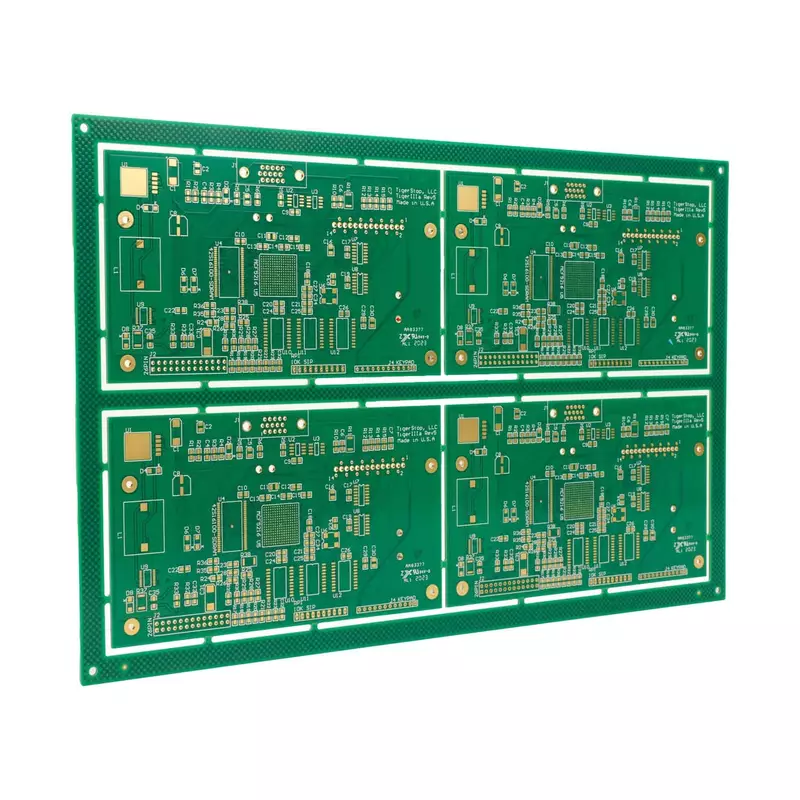

Rigid PCB Capability

Rigid PCBs are common used for laptop and desktop computers, audio keyboards, solid-state drives (SSDs), flat-screen TVs and monitors, children’s toys, and various electronic gadgets, etc. Most consumer electronics manufacturers will select rigid PCB for their application.

Technique Specifications As Reference

We custom the layers according to your requirements.

HDI stands for High Density Interconnector. A circuit board which has a higher wiring density per unit area as opposed to conventional board is called as HDI PCB. HDI PCBs have finer spaces and lines, minor vias and capture pads and higher connection pad density. It is helpful in enhancing electrical performance and reduction in weight and size of the equipment. HDI PCB is the better option for high-layer count and costly laminated boards.

Technique Specifications As Reference

We custom the layers according to your requirements.

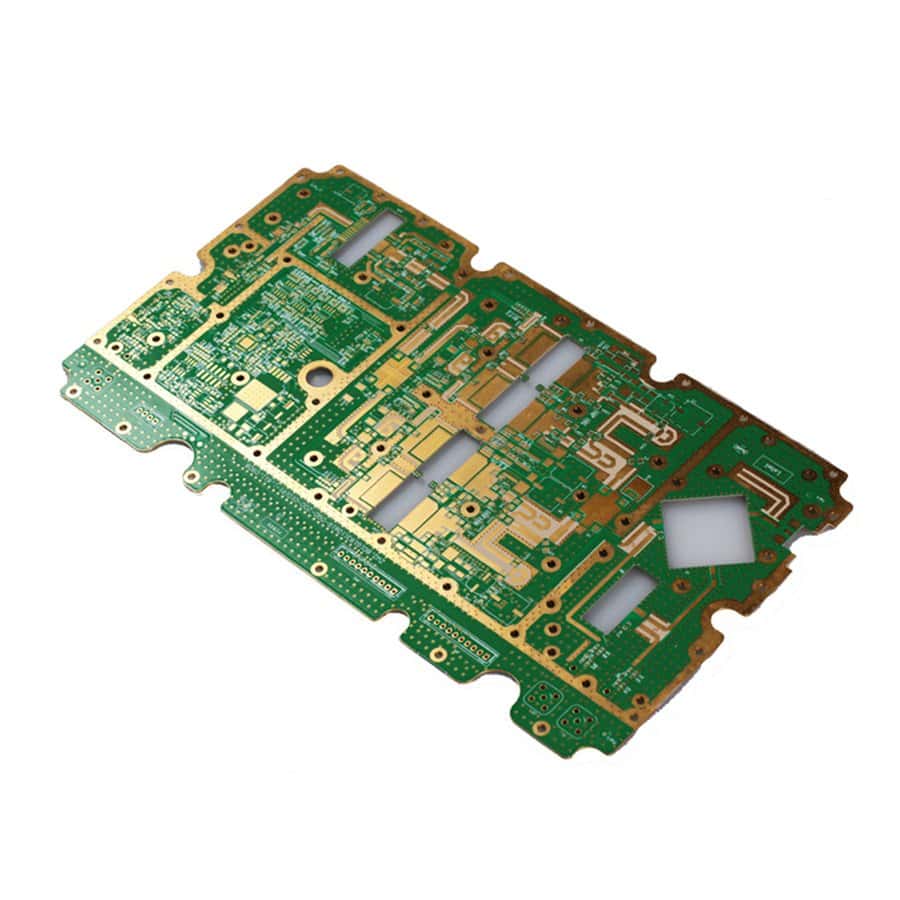

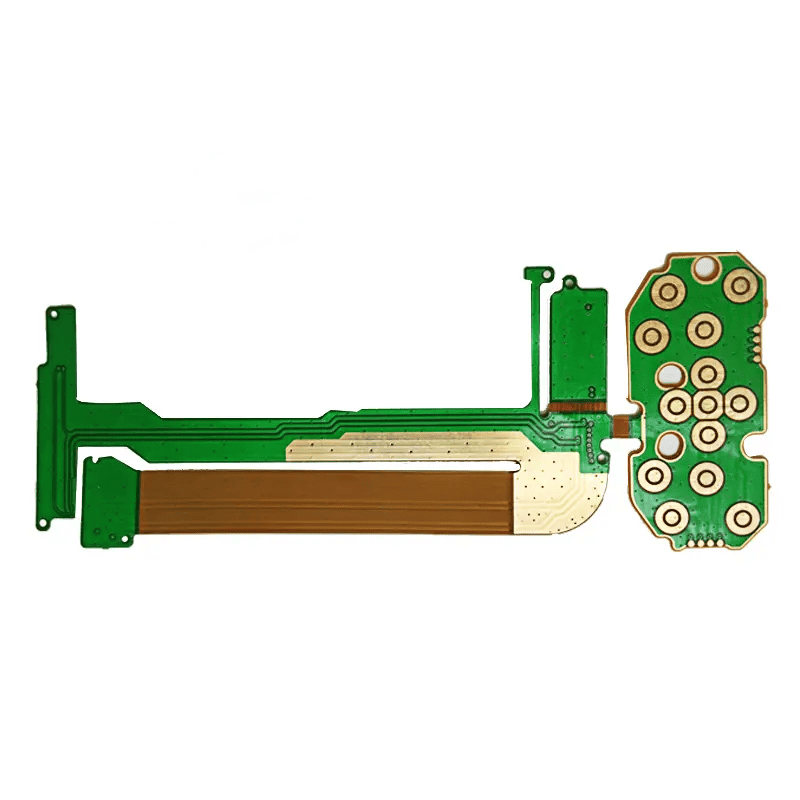

Rigid-Flex PCB Capability

Flex PCBs make installation much more easier for some applications. Combine rigid PCB and Flex PCB will be a good solution to avoid mounting issues. Rigid-Flex PCBs are common used for ultra-compact and/or high-performance devices, including GPS units, tablets, smart phones, cameras, and wearables.

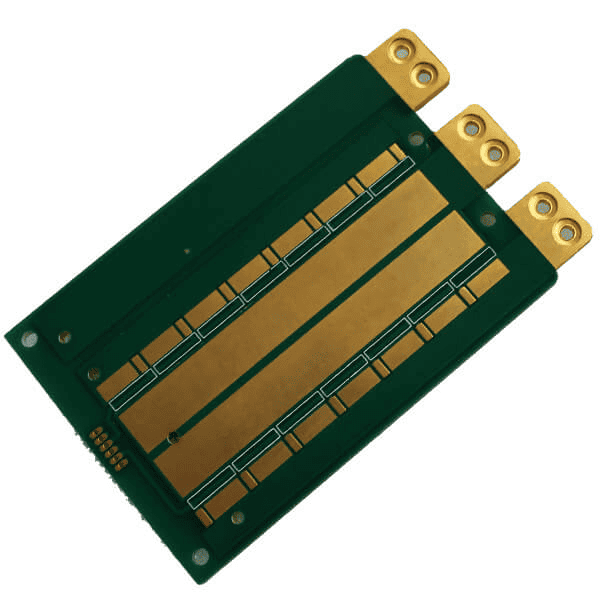

Metal PCB Capability

Metal PCB is the best solution to release the heat of the boards. For example, LEDs devices dissipate a lot of heat. Metal PCB can works great in LED lights, lamps, tube lights, car lights, etc. Other applications, like power supply, DC/DC and DC/AC converters. Also automotive, telecommunications, computers, power modules.

Technique Specifications As Reference

We custom the layers according to your requirements.

How We Do PCB Fabrication?

How PCB is manufactured? What is inside a PCB factory in China? You will see every production process when we manufacture PCB. Hope this video helps you understand PCB better and get general ideas about who we are and what we do.

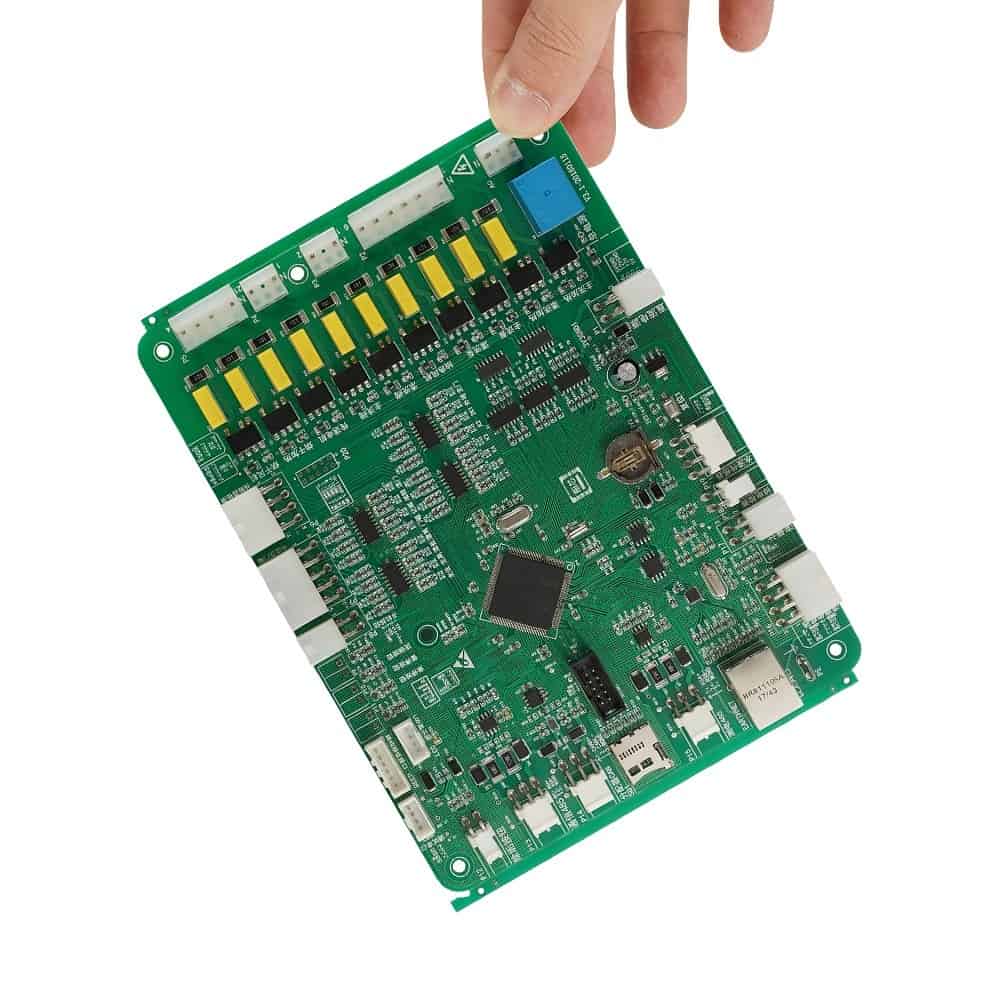

Wondering Whether We Make PCBA? Yes, We Do!!

The PCBAs We Made for Electronics Manufacturers

High-precision SMT Machinery

Equipped with high- precision automatic high-speed placement machine SMC and high-precision general-purpose machine SMD.

Offer Alternative Solutions

Other professional solutions to save your time and money will be provided according to customer's requirements.

Peferct Storage for Materials

Baking, hermetically sealing and storing MSD components that are sensitive to temperature and humidity.

Source Original components

All components will be sourced exactly the same brand and model in your BOM file. We respect every design from our customers.

GET YOUR SPECIFIC SOLUTION

We have engineers with 20 years experiences in PCB & PCBA ready here 24/7 to provide one-to-one evaluation of your Gerber or BOM file.

How We Can Do To Make Your Business Better?

What We Can Do for You?

One-Stop PCB Fabrication & PCB Assembly Solutions

QCX ELECTRONIC is a high-tech company focusing on PCB Manufacturing, PCB Assembly and Cоmроnеntѕ Sоurсing Sеrviсе more than 20 уеаrs.

We dedicate to produce various types of printed circuit boards , mainly include single-sided, double-sided, multilayer circuit boards, high precision HDI, flexible boards (FPC), rigid-flexible boards (including HDI) ,metal circuit boards and their SMD plug-ins.

PCB Prototype

Quickturn Low Cost Prototype to Volume Production Saving Your Time and Money

PCB Assembly

Reliable Components Sourcing Channel and SMT/DIP Assembly Production

PCB Fabrication

Make PCB on the Basis of Your Gerber File and Automated Lines to Handle PCB Manufacturing Process and Quality Control

Advanced Technology

✓ HDI ✓ Hard Gold Board ✓ High Frequency Board ✓ Cooper-base Board ✓ Ceramic Substrate board ✓ Transparent FPC

Application Fields We've Served

Consumer Electronics

PCB & PCBA for mobile, power bank, outdoor led light, camera, humidifier, etc.

Automative Industry

PCB & PCBA for car lights, engine, car door switch, instrument board, etc.

Industry Control

PCB & PCBA for PLC, touch screen, industrial computer, thermal relay, indicator light, etc.

Medical Industry

PCB & PCBA for electrophoresis, medical centrifuge, ECG diagnostic, ultrasonic diagnostic

Power & New Energy

PCB & PCBA for solar power plant, power generator, Environmental protection equipment

Telecom Electronics

PCB & PCBA for 5G facilities, Digital Television, Satellite Antenna, Walkie talkie, etc.

WHY CHOOSE US?

Our Facilities

100% AOI Inspection And Fully Compliant with Different Quality Standards

OUR ADVANTAGE

- Over 20 years of PCB Manufacturing & assembly experience

- No MOQ(Accept low & high volume order started from 1pcs)

- 7/24 Online & Tech Serivce

- 100+ professional engineers

- Quick Prototype(The fast lead time is 48 hours)

- Keep Your Information Safety

- Guarantee 100% on-time delivery

- Meet with UL, IATF16949, ISO, RoHs&Reach

EN

EN

RU

RU