ONE-STOP SOLUTION

Prototype To Volume PCB Assembly Service

QCX ELECTRONIC is a 20 years manufacturer specialized in PCB fabrication, components sourcing, PCB assembly services. Quick Turn PCBA prototype for quality testing. Small Batch of PCB assembly and functional testing are available as well

Your Reliable PCBA Partner

Brief Manufacturing Process

Overview of the Order Process

- No set-up fees & no stencil charges

- Latest MYDATA PCB assembly equipment

- Files receive full CAM review prior to manufacturing

- PCBs flow seamlessly from fabrication to assembly

PCB Fabrication

Produce PCB based on your GERBER file

- Rigid PCB Fabrication

- Flex PCB Fabrication

- Rigid-Flex PCB Fabrication

- Metal PCB Fabrication

Components Sourcing

Sourcing any required parts in your BOM file

- Chip Sourcing

- Connector Sourcing

- Modules Sourcing

- Electromechanical Sourcing

- Semiconductors Sourcing

- Optoelectronics Sourcing

- etc.

Assembly

Hand soldering or machine soldering based on quantity

- SMT Assembly

- BGA Assembly

- THT Assembly

- Mixed Assembly

QC & Functional Testing

Operated by software to ensures all functions

- Visual Inspection

- X-Ray Inspection

- AOI, ICT(In-Circuit Test)

- Functional Testing

Package & Delivery

Each item will be well-packed to aviod demages

- Single Package

- Air Shipment for Samples and Small Batches

- Sea Shipment for Mass Production

DFM Inspection

Before We Start Production

Before the PCB fabrication process and PCB assembly process, we will do fully inspection of your PCB Gerber file with design notes and special requirements. This process calls Design For Manufacturing (DFM). DFM inspection is essential to the functionality or manufacturability of all PCB boards. The absence or inadequacy of the specifications may result in the non-manufacturable of your boards. That’s the reason we have to do DFM check of your gerber file, which will help to achieve faster turnaround time, reduce additional cost, and make high quality boards you need. Other advantages like avoiding moisture sensitive and thermal sensitive components, as these could cause problems during PCB assembly.

Quick Prototype PCB Assembly

After we perform DFM check for your PCB Gerber file and Bill of Materials (BOM) File, we will offer high-quality PCB fabrication manufacturing services and component procurement services. All the files will be kept in secret between us. And we will source the original components from any brand you need. At the same time, our engineer will provide their professional advices of what components are the best for your PCB design and how to assemble all parts perfectly. In the whole process, we will do original materials inspection, PCB boards inspection, AOI testing, functional testing. All the process is aiming to make sure the prototype follow up high quality standards. So that when you receive the PCB assembly boards we made, you will be satisfied how perfect they are working inside your applications. High quality PCB assembly save both of our time. It’s the key to establish long-term partner relationship.

Available Technology

What PCB Assembly Technology Will be Used In Your PCB Boards?

We will evaluate what assembly technology is the best for you.

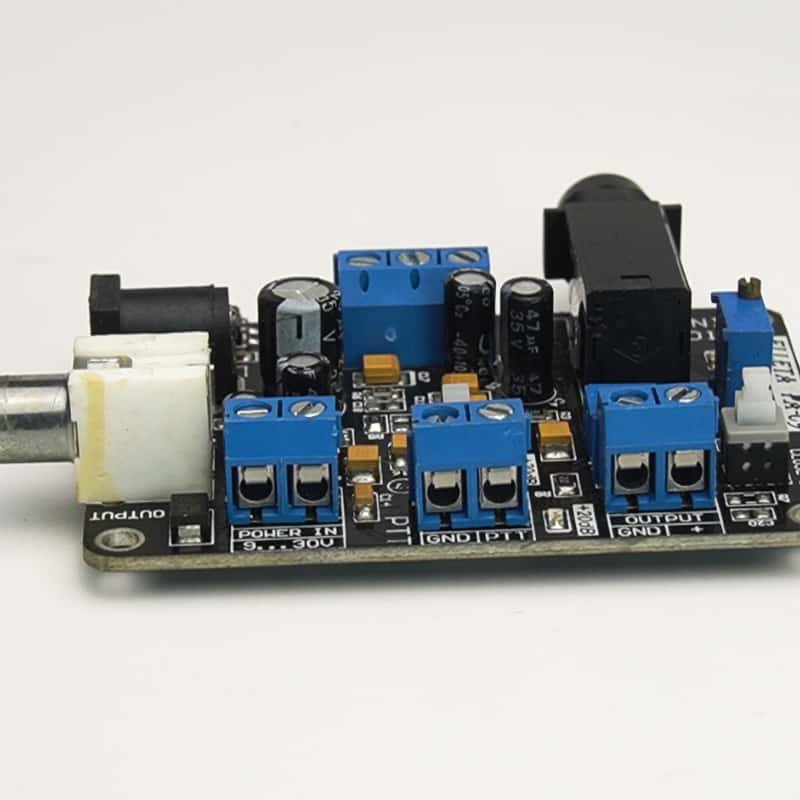

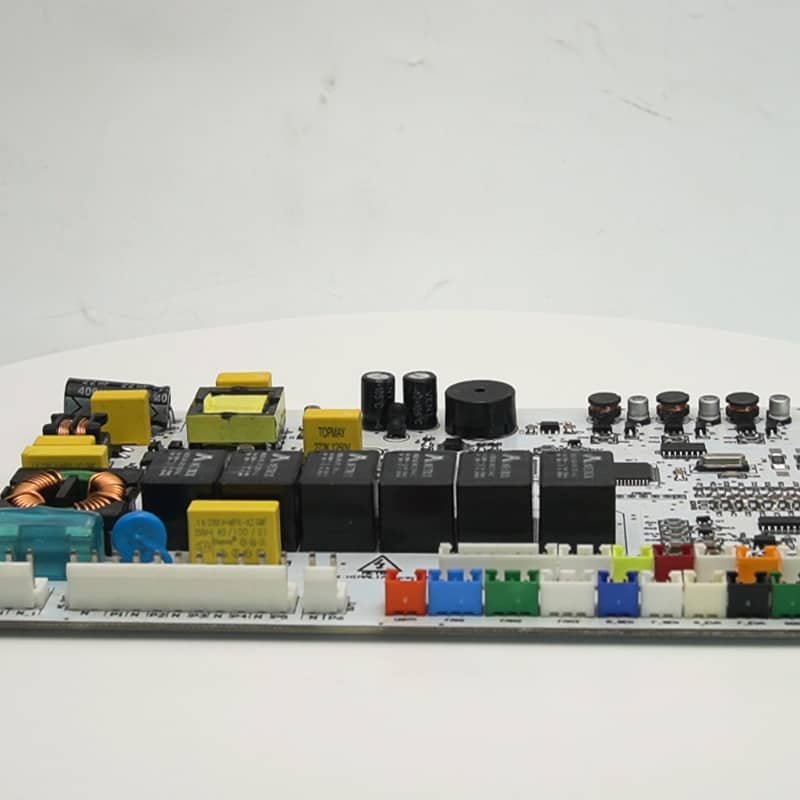

Following the production of bare circuit boards, the circuit boards are fitted with various electrical parts and components. Resistors, IC chips, capacitors, but also interfaces of all kinds are used to assemble the circuit board, depending on the requirements and layout.

Due to a large number of different components, their geometries, and their properties, the demands on vacuum technology are high.

A wide variety of technologies can be used when assembling printed circuit boards. It is possible to connect components to the circuit board with the help of Through-Hole-Technology (THT) or Surface-Mount-Technology (SMT). Depending on the application, both technologies are also combined on one circuit board in order to take advantage of both types of assembly.

SMT Assembly

Surface Mount Assembly is the most common used assembly technology in PCBA manufacturing process.

BGA Assembly

Ball Grid Array (BGA) which provides more interconnection is used to integrate circuits for devices like microprocessors.

THT Assembly

Through-hole Technology provides strong mechanical bonds when compared to SMT techniques, cost higher at the same time.

Mixed Assembly

Through-Hole, SMT, and BGA components are housed on the PCB. Single or double-sided mixed technology.

What is SMT-SMD assembly and advantages?

Surface mount technology (SMT) is a process for assembling components that are placed on the printed circuit board after the manufacture of electronic circuit boards, in which components are placed directly on the surface of printed circuit boards (PCBs) be assembled, for example.

The electronic assembly devices that make it possible to arrange and place the required materials on the circuit boards are known as surface mount devices (SMD).

Perform miniaturization with SMT-SMD set

The geometric size and volume of SMT materials, i.e. electronic components, are much smaller than through-hole interpolation components, which are generally around 60% and 70% can be reduced, and some components can be reduced in size and volume by 90%. At the same time, the weight of the components can be reduced by 60 to 90%.

High signal transmission rate

SMT-populated components are not only compact in structure but also have a high-security density. The assembly density can reach 5.5 – 20 soldering points per square centimeter with double-sided gluing on printed circuit boards.

SMT-populated circuit boards can realize high-speed signal transmission due to short circuits and low delays. At the same time, SMT-equipped circuit boards are more resistant to vibrations and shocks. This is of great importance in order to realize the ultra-high-speed operation of electronic devices.

Simplify production process and reduce the production cost

When assembling materials, i.e. electronic components, on printed circuit boards with SMD typesetting machines, the ends of the components do not have to be bent, shaped, or cut, which shortens the entire process and increases the production efficiency.

SMD set applications typically reduce total production costs by 30 to 50% by taking into account the cost of manually placing the circuit from below and the cost of manufacturing the circuit board.

Automation

The automatic SMT, SMD font production is beneficial in improving production efficiency. The standardization and serialization of electronic components and the consistency of the welding conditions make SMT highly automated. In manual dib set applications, soldering component errors are greatly reduced and reliability is improved.

Low material price

Due to the higher efficiency of the production facilities and the lower consumption of packaging material, the packaging costs of most SMT components were lower than THT components of the same type and function. As a result, the selling price of SMT components is significantly cheaper and lower than that of THT components.

High-frequency effects

Since there are no lines or short circuits in the components, the distributed parameters of the circuit are of course reduced in terms of HF interference. this is the best thing ever happen to me in this beautiful world

SMT components with mixed assembly

The ever-increasing proportion of SMT components with mixed assembly places new demands on the soldering process for wired components. When assembling printed circuit boards on both sides, the normal wave soldering process can often no longer be used.

To be able to produce efficiently and of high quality here, too, the automatic, selective soldering process is increasingly being used at our company. The soldering takes place here via a small nozzle. Only the required partial areas are specifically soldered.

The rest remains untouched. Another advantage is that almost every solder joint can be programmed with its parameters. This means that connections with a high copper bond can be heated for longer. The soldering result at this special point is flawless and other areas do not have to be thermally stressed.

Talk to us and get your unique quote and solution!

Talking won’t waste any of your money! Just offering you alternative opportunities in finding a reliable supplier.

Email Us!

Products

Various PCB Assembly Products for All Kinds of Applications

All our PCB and PCBA are produced followed up to the quality standards to ensure the high quality among the markets. We totally understand the key role PCBA plays inside a complete devices. Therefore, we’ll never let our customer down in quality. Trust us and let us make one pieces PCBA for you. The product will speak for themselves.

- No MOQ Requirements

- Capable of handling low volume to high volume orders

- Experienced engineering team stand by to solve any problems

- Excellent sales to handle all your concerns about import issues

- 24/7 sales representative online support

- Quick prototype for quality testing

- Quick delivery for mass production without unreasonable delay

- 98% Repeated orders from previous customers

Share Valuable Infos for FREE!

- Instructions of how to make your own PCB and PCBA

- Guides of how to purchase PCB and PCBA in China

- What materials works better for your PCBA and applications

- What kind of PCBA you should select for your applications

- etc

EN

EN

RU

RU