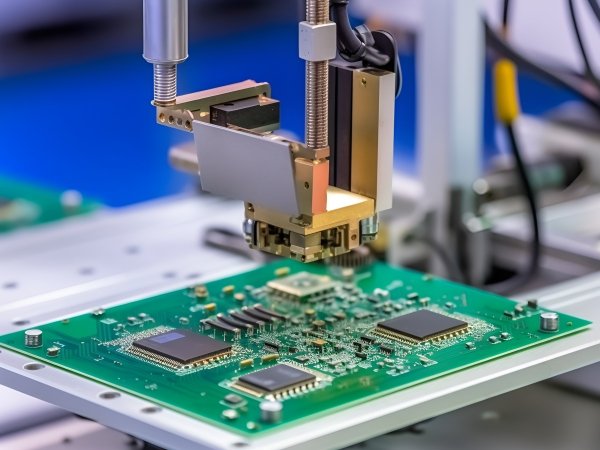

Quickturn PCB Prototype Manufacturer

An electronic PCB is constructed by utilizing the specifications contained in the PCB design package to transform it into a physical object. Printed circuit boards are made by applying layers on a circuit board with a certain pattern on its surface in order to make them suitable for electronic manufacturing.

Fast PCB Prototype

Since the purpose of a printed circuit board prototype is to test the actual layout of the system, it is acceptable to use a different manufacturing process for small quantities of printed circuit board prototypes.

- Rigid PCB Prototype

- Flex PCB Prototype

- Rigid-flex PCB Prototype

- Metal PCB Prototype

Low Volume PCB Fabrication

A printed circuit board is a flat laminated composite made from a non-conductive substrate material with a copper layer buried beneath its outer surface. Copper plates or substrates can be cut to reveal the design depending on the requirements. In designing and manufacturing multilayer printed circuit boards, additional steps are required to take into account the additional layers. Printed circuit boards with multiple layers use thin single circuit boards and a layer between them that are connected to create an entire circuit board. Multi-layer circuit boards are manufactured using a multi-layer printing process that utilizes layers such as composite layers, copper layers, and insulation layers.

- Single-layer PCB Fabrication

- Double-side PCB Fabrication

- Multi-layer PCB Fabrication

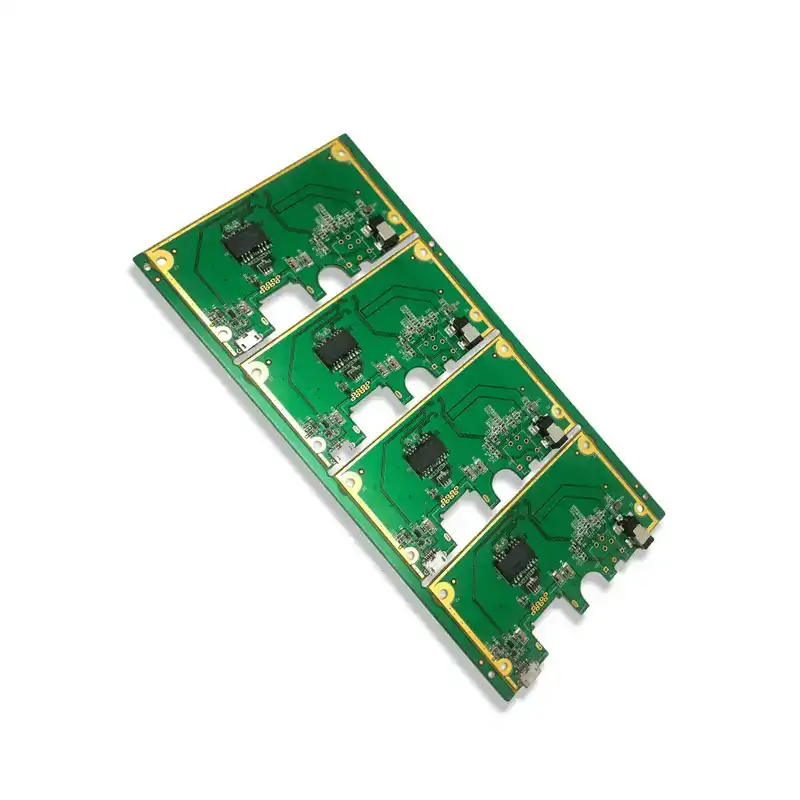

Rigid pcb

Rigid PCBs are commonly used for laptop and desktop computers, audio keyboards, solid-state drives (SSDs), flat-screen TVs and monitors, children’s toys, and various electronic gadgets, etc. Most consumer electronics manufacturers will select rigid PCBs for their applications.

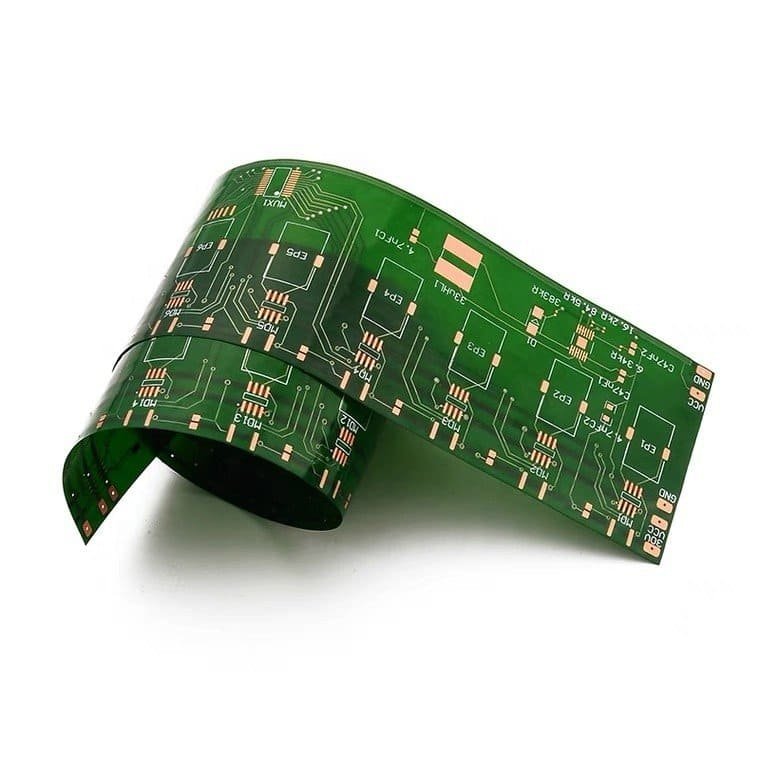

Flex PCB

Flex PCBs make installation much easier for some applications because they have incomparable flexibility, save space, and are easier to maintain than rigid circuit boards in the later period. Flexible circuits are commonly used in computer keyboards; most keyboards use flexible circuits as switching matrices.

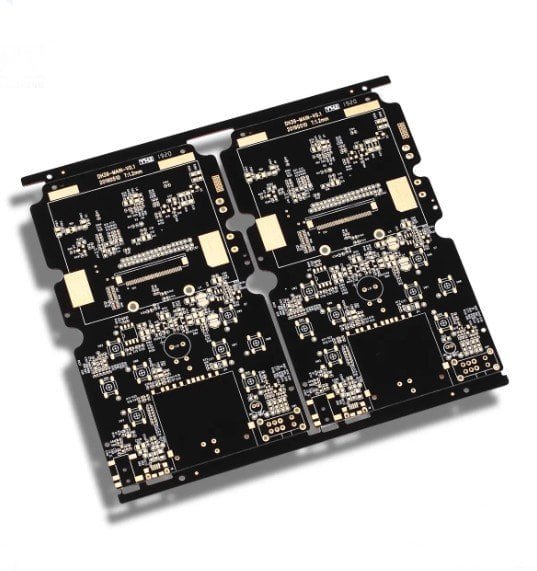

Rigid-flex PCB

Flex PCBs make installation much more easier for some applications. Combine rigid PCB and Flex PCB will be a good solution to avoid mounting issues. Rigid-Flex PCBs are common used for ultra-compact and/or high-performance devices, including GPS units, tablets, smart phones, cameras, and wearables.

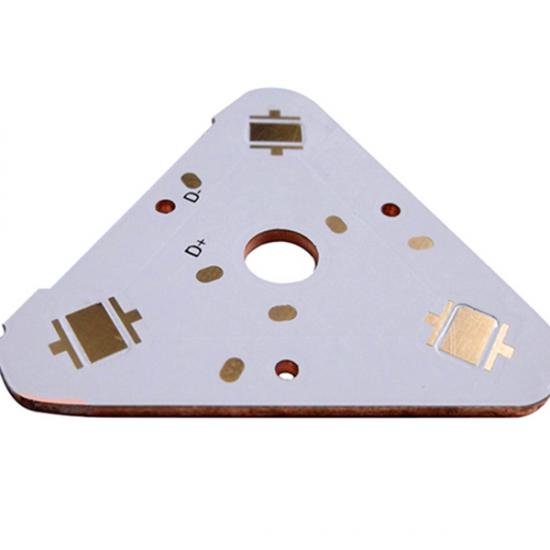

Metal PCB

A metal-core printed circuit board (Metal PCB) utilizes a metal layer, such as copper or aluminum, as the core material for the circuit board. This type of PCB provides enhanced thermal conductivity, improved electrical performance, and higher stiffness compared to traditional fiberglass-based PCBs.

Why Choose Us?

QCX ELECTRONIC is a high-tech company focusing on PCB Manufacturing, PCB Assembly and Cоmроnеntѕ Sоurсing Sеrviсе more than 19 уеаrs.

We dedicate to produce various types of printed circuit boards , mainly include single-sided, double-sided, multilayer circuit boards, high precision HDI, flexible boards (FPC), rigid-flexible boards (including HDI) ,metal circuit boards and their SMD plug-ins. Our monthly production capacity reaching over 5,000 models, 200,000 square meters and EMS assembling capacity at 150,000,000 components .

What Do Our Customers Say?

EN

EN

RU

RU